Troubleshooting electrical issues in an automobile can be a daunting task.

However, technicians have a valuable tool at their disposal—the automotive breakout box.

This device simplifies the process of identifying and resolving electrical problems in vehicles.

But what exactly is an automotive breakout box and how does it work?

An automotive breakout box, often referred to as a diagnostic breakout box or simply a breakout box, is a specialized tool designed to facilitate the testing and analysis of a vehicle’s electrical system.

It serves as an intermediary between the electronic control module (ECM) or electronic control unit (ECU) and the various sensors, actuators, and wiring harnesses in a vehicle.

Key Components and Design of an automotive breakout box

-

Connectors

Breakout boxes feature a variety of connectors that mimic the connections found in a vehicle’s wiring system.

These connectors allow technicians to easily interface with the ECM, sensors, and other components.

-

LED Indicators

Equipped with LED indicators, breakout boxes provide visual feedback to technicians.

These indicators light up when there is electrical activity, aiding in the quick identification of potential issues.

-

Switches

Some breakout boxes include switches that enable technicians to open or close specific circuits manually.

This allows for controlled testing and isolation of individual components.

How does automotive breakout box work?

-

Connection to the Vehicle

The breakout box is connected between the ECM/ECU and the vehicle’s wiring harness.

This is done by unplugging the connectors from the ECM and inserting them into the corresponding connectors on the breakout box.

-

Monitoring and Testing

Once connected, the breakout box allows technicians to monitor signals passing through the electrical system.

The LED indicators provide real-time feedback on the status of various circuits, helping identify any irregularities.

-

Isolation of Components

By using the switches on the breakout box, technicians can selectively isolate specific components or circuits.

This step-by-step approach helps pinpoint the source of electrical issues without affecting the entire system.

-

Diagnostic Tool Compatibility

Breakout boxes are often compatible with diagnostic tools, allowing technicians to integrate additional testing and analysis capabilities. This enhances the precision and efficiency of the diagnostic process.

Benefits of Using an Automotive Breakout Box

-

Time-Saving

Breakout boxes streamline the diagnostic process by allowing technicians to focus on specific components without dismantling the entire wiring system.

-

Precision in Troubleshooting

The ability to isolate and test individual components helps in accurately identifying and resolving electrical issues, minimizing guesswork.

-

Minimized Risk of Damage

By preventing unnecessary manipulation of wiring harnesses, breakout boxes reduce the risk of damaging sensitive electronic components during the diagnostic process.

An automotive breakout box emerges as a valuable ally for technicians, simplifying the process of troubleshooting electrical issues.

Its ability to interface with a vehicle’s electrical system, monitor signals, and selectively isolate components makes it an indispensable tool in the modern automotive workshop.

As technology continues to evolve, breakout boxes will likely play an even more significant role in ensuring efficient and accurate diagnosis and repair of electrical problems in vehicles.

How can an automotive breakout box help diagnose vehicle electrical issues?

Here’s how an automotive breakout box can help identify and resolve electrical problems in a vehicle:

-

Signal Monitoring

Breakout boxes allow technicians to monitor signals flowing between the electronic control module (ECM) or electronic control unit (ECU) and various components in the vehicle.

This real-time monitoring helps identify irregularities or fluctuations in signals, providing clues about potential issues.

-

Isolation of Components

Technicians can use the breakout box to selectively isolate specific components or circuits within the vehicle’s electrical system.

By doing so, they can focus on testing individual elements without interference from the rest of the system.

This isolation is crucial for pinpointing the source of a problem accurately.

-

Manual Circuit Control

Some breakout boxes come equipped with switches that enable technicians to manually open or close circuits.

This feature allows for controlled testing of specific components, helping to determine if a particular circuit is functioning as expected.

-

Identification of Faulty Components

By systematically isolating and testing different components, technicians can identify which part of the electrical system is malfunctioning.

This targeted approach significantly reduces the time and effort required to pinpoint the root cause of the issue.

-

Visual Feedback

Breakout boxes often include LED indicators that provide visual feedback on the status of various circuits.

These indicators can quickly alert technicians to the presence of signals and help identify areas that require closer inspection.

-

Integration with Diagnostic Tools

Many breakout boxes are compatible with diagnostic tools, enhancing their functionality.

Technicians can integrate these tools to access additional data, perform advanced tests, and gather more comprehensive information about the vehicle’s electrical system.

-

Minimized Risk of Damage

Since breakout boxes allow technicians to interact with the electrical system without physically manipulating the vehicle’s wiring, there is a reduced risk of damage to sensitive components.

This is particularly important when dealing with modern vehicles with intricate electronic systems.

-

Efficient Troubleshooting

The systematic and controlled nature of using a breakout box streamlines the troubleshooting process.

Technicians can progress through different circuits and components, eliminating possibilities and narrowing down the scope of the problem efficiently.

-

Educational Tool

Breakout boxes can serve as valuable educational tools for technicians and students learning about automotive electronics.

They provide a hands-on and visual way to understand the intricacies of a vehicle’s electrical system.

An automotive breakout box is a versatile tool that empowers technicians to diagnose vehicle electrical issues with precision and efficiency.

By monitoring signals, isolating components, and providing visual feedback, breakout boxes play a crucial role in the diagnostic process, ultimately leading to faster and more accurate resolutions to electrical problems in vehicles.

Are there different types of automotive breakout boxes available? If so, which one would be suitable for my needs?

Yes, there are different types of automotive breakout boxes available, each designed for specific purposes and compatibility with various vehicles.

Choosing the right one for your needs depends on the type of vehicle you’re working on, the complexity of its electrical system, and the specific diagnostic tasks you want to perform.

Here are some common types of automotive breakout boxes:

1. Generic Breakout Boxes

These are versatile breakout boxes designed to work with a wide range of vehicles.

They often come with a variety of connectors and switches to accommodate different wiring configurations.

Generic breakout boxes are suitable for general diagnostic tasks and are commonly used in workshops that deal with a variety of vehicle makes and models.

2. Manufacturer-Specific Breakout Boxes

Some breakout boxes are specifically designed for use with vehicles from a particular manufacturer.

These boxes are tailored to the unique wiring and communication protocols of that manufacturer’s vehicles.

If you primarily work on a specific brand of vehicles, a manufacturer-specific breakout box can provide enhanced compatibility and functionality.

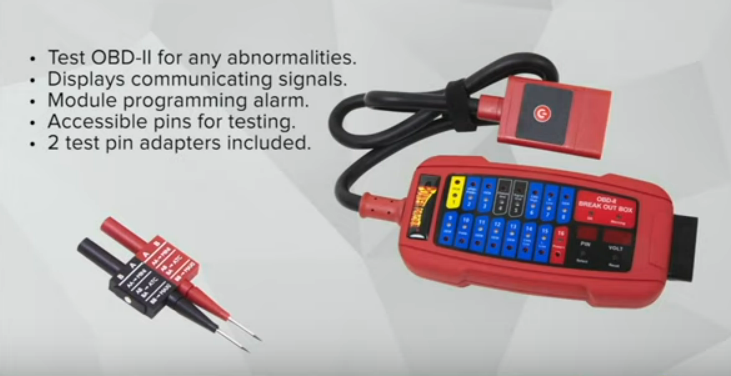

3. OBD-II Breakout Boxes

On-Board Diagnostics II (OBD-II) breakout boxes are designed to interface with a vehicle’s OBD-II port.

These boxes allow technicians to access and monitor the standardized diagnostic information available through the OBD-II system.

OBD-II breakout boxes are commonly used for reading trouble codes, live data, and performing basic diagnostics.

4. CAN Breakout Boxes

Controller Area Network (CAN) breakout boxes are specialized tools designed to work with vehicles that utilize CAN communication protocols.

CAN is prevalent in modern vehicles for its efficiency in transmitting data between various electronic control units.

If you frequently work on newer vehicles, a CAN breakout box may be essential for effective diagnostics.

5. Multiplex Breakout Boxes

Multiplex breakout boxes are designed to handle the complex wiring systems found in multiplexed or networked vehicles.

These vehicles use communication networks to transmit data between electronic components.

A multiplex breakout box helps diagnose issues related to these interconnected systems.

6. Advanced Diagnostic Breakout Boxes

Some breakout boxes come equipped with advanced features, such as data logging, signal waveform analysis, and compatibility with diagnostic software.

These tools offer more comprehensive diagnostic capabilities and are suitable for professional technicians working on intricate electrical issues.

When choosing a breakout box, consider the specific requirements of your diagnostic tasks and the types of vehicles you frequently encounter.

If you work with a diverse range of vehicles, a versatile generic breakout box may be a good starting point.

For more specialized needs, such as working with a particular manufacturer or dealing with advanced diagnostic tasks, a manufacturer-specific or advanced diagnostic breakout box may be more suitable.

Always check the compatibility of the breakout box with the vehicles you’ll be working on and ensure that it meets your specific diagnostic needs.

Can an automotive breakout box be used with any make or model of vehicle?

In general, automotive breakout boxes are designed to be versatile and compatible with a wide range of vehicles.

However, there are a few considerations to keep in mind:

-

Connector Compatibility

Different vehicles may use different types of connectors for their electronic control modules (ECMs) or other components.

While many breakout boxes come with a variety of connectors to accommodate various wiring configurations, it’s essential to ensure that the breakout box you choose has the appropriate connectors for the vehicles you’ll be working on.

-

Communication Protocols

Vehicles use different communication protocols for their electronic systems.

For example, some vehicles use the Controller Area Network (CAN) protocol, while others may use older protocols such as ISO 9141 or KWP2000.

Ensure that the breakout box supports the communication protocols used by the vehicles you intend to diagnose.

-

Manufacturer-Specific Considerations

Some breakout boxes are designed to be manufacturer-specific, meaning they are optimized for use with vehicles from a particular automaker.

These boxes may have features tailored to the unique wiring and communication protocols of that manufacturer’s vehicles.

If you predominantly work on a specific brand, a manufacturer-specific breakout box might offer enhanced compatibility and functionality.

-

OBD-II Compatibility

If you are primarily interested in basic diagnostics and reading standard OBD-II trouble codes, a breakout box that interfaces with the OBD-II port could be suitable for a wide range of vehicles. However, keep in mind that not all diagnostic tasks can be performed solely through the OBD-II port, and more advanced breakout boxes may be required for in-depth troubleshooting.

-

Multiplexing and Networked Systems

Some modern vehicles feature multiplexed or networked electrical systems, where components communicate with each other through data networks.

If you frequently work on such vehicles, you may need a breakout box designed to handle the complexities of multiplexed systems.

Before purchasing or using an automotive breakout box, review the specifications and features to ensure compatibility with the makes and models of vehicles you commonly encounter in your work.

Also, consider the type of diagnostic tasks you need to perform, as more specialized breakout boxes may be necessary for advanced troubleshooting and analysis.

Always consult the user manual and guidelines provided with the breakout box to ensure proper usage and compatibility.

What are the key features and functions of a high-quality automotive breakout box?

A high-quality automotive breakout box is a crucial tool for effective vehicle diagnostics.

Here are key features and functions to look for when considering a breakout box:

-

Versatile Connectors

A good breakout box should come with a variety of connectors to accommodate different types of wiring configurations found in various vehicles.

Ensure that it includes connectors for the specific makes and models you work on.

-

Compatibility with Communication Protocols

Vehicles use different communication protocols, such as CAN (Controller Area Network), ISO 9141, and KWP2000. The breakout box should support the communication protocols used by the vehicles you intend to diagnose.

-

Manufacturer-Specific Compatibility

Some breakout boxes are designed for use with specific vehicle manufacturers.

If you frequently work on vehicles from a particular brand, a manufacturer-specific breakout box may provide enhanced compatibility and features tailored to that manufacturer’s systems.

-

OBD-II Compatibility

If your diagnostic needs include reading standard OBD-II trouble codes, ensure that the breakout box interfaces with the OBD-II port.

This is essential for basic diagnostics and accessing standardized information from the vehicle’s onboard computer.

-

LED Indicators

LED indicators on the breakout box provide visual feedback, allowing technicians to quickly identify the status of various circuits and signals.

These indicators enhance the efficiency of the diagnostic process by providing real-time information.

-

Switches for Circuit Control

Some breakout boxes include switches that allow technicians to manually open or close circuits.

This feature is valuable for controlled testing, isolation of components, and systematic troubleshooting.

-

Diagnostic Tool Integration

A high-quality breakout box should be compatible with diagnostic tools, enabling technicians to integrate additional testing and analysis capabilities. This integration enhances the precision and depth of the diagnostic process.

-

Durability and Build Quality

Given the demanding nature of automotive diagnostics, a breakout box should be built with durability in mind.

Look for robust construction, quality materials, and reliable connectors to ensure the tool can withstand the rigors of regular use.

-

Data Logging Capability

Some advanced breakout boxes offer data logging functionality, allowing technicians to record and analyze signals over time.

This feature can be valuable for diagnosing intermittent issues or capturing data during specific driving conditions.

-

User-Friendly Design

An intuitive and user-friendly design, including clear labeling and easy-to-use controls, is essential for technicians to navigate the breakout box efficiently and effectively during diagnostics.

-

Multiplex System Support

If you work on vehicles with multiplexed or networked electrical systems, ensure that the breakout box is equipped to handle the complexities of these systems.

-

Grounding Points

Some breakout boxes include additional grounding points, aiding in maintaining a stable electrical connection during testing.

When evaluating a breakout box, consider your specific diagnostic needs, the types of vehicles you commonly work on, and the level of functionality required.

Investing in a high-quality breakout box can significantly improve the accuracy and efficiency of your vehicle diagnostics.

Is it easy to use an automotive breakout box, or do I need specialized knowledge?

Using an automotive breakout box vary in difficulty depending on your level of experience with vehicle diagnostics and electrical systems.

Here’s a general overview:

For Novice Users

- Basic Connections

The initial steps involve connecting the breakout box between the electronic control module (ECM) or electronic control unit (ECU) and the vehicle’s wiring harness.

This usually involves unplugging the connectors from the ECM and inserting them into the corresponding connectors on the breakout box.

- LED Indicators

Many breakout boxes come with LED indicators that provide visual feedback on the status of various circuits.

Novice users can rely on these indicators to observe the presence of signals and quickly identify potential issues.

- Manual Switches

Some breakout boxes have manual switches to control circuits. While this adds a level of complexity, basic operations involve opening or closing circuits for controlled testing.

For Intermediate Users

- Understanding Diagnostic Tasks

Intermediate users should have a basic understanding of common diagnostic tasks, such as identifying signals, testing individual circuits, and isolating components.

- Troubleshooting Techniques

Knowledge of troubleshooting techniques becomes more important at this level.

Users should be comfortable systematically isolating and testing different components to identify the source of electrical issues.

- Diagnostic Tool Integration

Intermediate users may explore integrating diagnostic tools with the breakout box for more advanced analysis.

Familiarity with diagnostic software and interpreting data becomes beneficial.

For Advanced Users

- Advanced Diagnostic Techniques

Advanced users are expected to be proficient in advanced diagnostic techniques, such as analyzing signal waveforms, interpreting data logs, and using specialized tools for in-depth troubleshooting.

- Multiplex Systems

Users dealing with vehicles with multiplexed or networked systems should be well-versed in the complexities of these setups.

- Manufacturer-Specific Knowledge

For those using manufacturer-specific breakout boxes, a deep understanding of the specific manufacturer’s wiring and communication protocols is essential.

General Tips for All Users

-

User Manuals

Always refer to the user manual provided with the breakout box. It will guide you through the specific functionalities and usage instructions.

-

Training and Education

Consider seeking training or education in automotive diagnostics, especially if you plan to use advanced features of breakout boxes.

Many technical schools and training programs offer courses in automotive technology.

-

Start with Basic Tasks

If you’re new to using breakout boxes, start with basic diagnostic tasks and gradually progress to more complex operations as you gain confidence and experience.

While using a breakout box may seem straightforward for basic tasks, gaining proficiency in advanced diagnostic techniques require some specialized knowledge and experience.

Continuous learning and hands-on experience will contribute to your effectiveness in using an automotive breakout box for diagnosing vehicle electrical issues.

Are there any safety precautions I should take when using an automotive breakout box?

Absolutely, working with automotive breakout boxes involves interacting with a vehicle’s electrical system, which requires careful attention to safety.

Here are some essential safety precautions to keep in mind:

-

Disconnect the Battery

Before connecting or disconnecting any components, always disconnect the vehicle’s battery.

This minimizes the risk of electrical shock and protects both you and the vehicle’s electronic components.

-

Follow Manufacturer Guidelines

Adhere to the specific guidelines and safety precautions outlined in the user manual provided with the breakout box.

Different models have unique features and requirements.

-

Wear Personal Protective Equipment (PPE)

Consider wearing appropriate personal protective equipment, including safety glasses and gloves.

This helps protect against potential hazards and ensures a safer working environment.

-

Ensure Proper Grounding

Properly ground both the vehicle and the breakout box to prevent electrical damage and ensure accurate readings.

Follow the manufacturer’s recommendations for grounding points.

-

Inspect Cables and Connectors

Before connecting the breakout box, carefully inspect cables and connectors for any signs of wear, damage, or corrosion.

Faulty connections can lead to unreliable readings and potential safety hazards.

-

Avoid Pinching Cables

When closing the vehicle’s hood or doors, be cautious not to pinch any breakout box cables.

Pinched cables can cause damage, affect performance, and pose safety risks.

-

Use the Right Tools

Use insulated tools when working with the breakout box to prevent accidental short circuits.

Avoid using tools with damaged insulation.

-

Work in a Well-Ventilated Area

If you’re working indoors, ensure adequate ventilation.

Some diagnostic tasks involve running the vehicle, and proper ventilation helps disperse exhaust gases.

-

Be Mindful of Moving Parts

When working around the vehicle, especially if the engine is running, be aware of moving parts such as belts and fans.

Keep loose clothing, jewelry, and hair secured to prevent entanglement.

-

Educate Yourself

Make sure you are well-educated on the specific electrical systems of the vehicles you are working on.

Understanding the vehicle’s wiring diagram and electrical components is crucial for safe and effective diagnostics.

-

Emergency Preparedness

Have safety equipment and emergency tools readily available.

This includes a fire extinguisher, a first aid kit, and an emergency stop plan in case of unexpected issues.

-

Secure the Vehicle

Ensure the vehicle is securely parked, especially if you are running the engine for diagnostic purposes.

Apply the parking brake, and if possible, use wheel chocks to prevent unintended movement.

-

Stay Informed on Vehicle Recalls

Be aware of any recalls or safety-related issues for the specific make and model of the vehicle you are working on.

This information can guide you in identifying potential hazards.

Always prioritize safety when working with automotive breakout boxes.

Taking the time to implement these precautions not only protects you but also ensures the integrity of the diagnostic process and the well-being of the vehicle’s electrical system.

Can an automotive breakout box save me time and money on vehicle repairs?

Yes, an automotive breakout box can be a valuable tool that saves both time and money in the vehicle repair process.

Here’s how:

-

Efficient Diagnostics

Breakout boxes allow for systematic and efficient diagnostics of a vehicle’s electrical system.

By quickly identifying and isolating the source of electrical issues, technicians can reduce the time spent on troubleshooting.

-

Pinpointing Issues Quickly

The ability to monitor signals, isolate components, and analyze data with a breakout box helps technicians pinpoint issues more rapidly.

This targeted approach reduces the need for time-consuming trial-and-error methods.

-

Minimizing Guesswork

Breakout boxes reduce guesswork by providing visual feedback and allowing controlled testing of individual components.

This helps technicians make informed decisions, leading to more accurate diagnoses and quicker repairs.

-

Preventing Unnecessary Parts Replacement

Efficient diagnostics with a breakout box can prevent the unnecessary replacement of parts.

Technicians can identify the specific faulty component, avoiding the cost of replacing functional parts and reducing overall repair expenses.

-

Avoiding Labor Costs

The time saved in the diagnostic process translates to reduced labor costs.

With a breakout box, technicians can streamline the troubleshooting process, enabling them to focus on targeted repairs and minimizing unnecessary hours spent on diagnosis.

-

Accurate Repair Estimates

Quick and accurate diagnostics using a breakout box contribute to more precise repair estimates.

This benefits both the technician and the vehicle owner by providing a clearer understanding of the necessary repairs and associated costs.

-

Increased Productivity

Automotive breakout boxes enhance the productivity of technicians by allowing them to work more efficiently.

This can result in faster turnaround times for vehicle repairs, ultimately saving time for both the technician and the customer.

-

Preventing Damage to Sensitive Components

Breakout boxes provide a controlled environment for testing, reducing the risk of accidental damage to sensitive electronic components during the diagnostic process.

This can prevent costly repairs resulting from mishandling.

-

Enhancing Customer Satisfaction

Timely and accurate diagnostics contribute to improved customer satisfaction.

When customers experience quicker turnaround times and cost-effective repairs, they are more likely to trust and return to the service provider for future automotive needs.

-

Reducing Return Visits

The precision afforded by breakout box diagnostics helps ensure that identified issues are effectively addressed.

This reduces the likelihood of customers returning with the same problem, saving time and resources for both the technician and the vehicle owner.

While an automotive breakout box is an investment, its potential to streamline diagnostics and reduce repair times can contribute to significant long-term savings.

It enables technicians to work more efficiently, make informed decisions, and provide customers with accurate repair estimates, ultimately leading to a more cost-effective and satisfying repair experience.

Are there any recommended brands or models of automotive breakout boxes in the market?

Here are some well-known brands that were recognized for producing quality automotive diagnostic tools, including breakout boxes:

-

Snap-on

Snap-on is a reputable brand known for manufacturing high-quality diagnostic tools and equipment.

Their breakout boxes are designed to work seamlessly with a variety of vehicles and offer advanced features.

2. Autel

Autel is a well-regarded brand in the automotive diagnostic tool industry.

They produce a range of diagnostic equipment, including breakout boxes, that are known for their reliability and versatility.

3. Launch Tech

Launch Tech is another brand that provides diagnostic solutions for the automotive industry.

Their breakout boxes are designed to assist technicians in efficiently diagnosing and troubleshooting electrical issues.

4. Bosch

Bosch is a trusted name in the automotive industry, known for producing a wide range of automotive components and diagnostic tools.

Their breakout boxes are designed to meet professional standards.

5. Actron

Actron produces diagnostic tools and equipment, including breakout boxes, suitable for both professional technicians and DIY enthusiasts.

Their products are known for their user-friendly design.

6. Pico Technology

Pico Technology is recognized for manufacturing high-quality oscilloscopes and related accessories, including breakout boxes.

Their products are often used for advanced diagnostic and waveform analysis.

7. AESwave

AESwave is a company specializing in automotive diagnostic equipment, and they offer breakout boxes designed for various diagnostic tasks.

Their products are known for their durability and functionality.

When choosing an automotive breakout box, consider the specific features you need, compatibility with the vehicles you work on, and the level of diagnostics you intend to perform.

Also, check for user reviews and ratings to gauge the real-world performance and reliability of the breakout box you are considering.

How reliable are the diagnostic results obtained from an automotive breakout box?

The reliability of diagnostic results obtained from an automotive breakout box depends on the quality of the breakout box itself, the proficiency of the technician using it, and the complexity of the vehicle’s electrical system.

Here are key considerations:

-

Quality of the Breakout Box

High-quality breakout boxes from reputable manufacturers are designed to provide accurate and reliable diagnostic results.

These boxes meet industry standards, have quality connectors, and offer features that enhance the precision of diagnostics.

-

Proper Usage by Technicians

The reliability of diagnostic results heavily relies on the knowledge and skill of the technician using the breakout box.

A well-trained and experienced technician is more likely to interpret signals correctly, identify issues accurately, and use the breakout box effectively.

-

Compatibility with Vehicle Systems

Breakout boxes need to be compatible with the communication protocols and electrical systems of the vehicles they are intended to diagnose.

Using a breakout box that aligns with the specific make and model of the vehicle is crucial for reliable results.

-

Correct Interpretation of Signals

Interpreting signals correctly is a critical aspect of using a breakout box.

Technicians need to understand the expected signal patterns for various components and systems.

Misinterpretation can lead to inaccurate diagnoses.

-

Quality of Wiring and Connectors

The reliability of diagnostic results can be affected by the condition of the vehicle’s wiring and connectors.

Damaged or corroded wiring can introduce anomalies in the signals, leading to misleading diagnostic readings.

-

Environmental Conditions

The diagnostic process may be influenced by environmental conditions, such as electromagnetic interference or poor grounding.

Adequate precautions, like proper grounding and working in a controlled environment, can contribute to more reliable results.

-

Advanced Diagnostic Capabilities

Some breakout boxes offer advanced diagnostic features, such as data logging and waveform analysis.

When used correctly, these capabilities can provide valuable insights into intermittent issues and complex electrical problems.

-

Verification through Multiple Methods

It’s good practice for technicians to verify diagnostic results through multiple methods, including using other diagnostic tools and conducting physical inspections.

Cross-referencing results helps ensure the accuracy of the diagnosis.

-

Continuous Training and Updates

As vehicle technology evolves, continuous training and staying updated on the latest diagnostic techniques are crucial.

Breakout box users should be aware of advancements in automotive technology and diagnostic methods to maintain reliable results.

While automotive breakout boxes are valuable tools for diagnosing electrical issues, it’s important to approach the diagnostic process with a comprehensive understanding of the vehicle’s systems and the limitations of the equipment.

When used by trained professionals in the appropriate context, breakout boxes contribute significantly to reliable and accurate diagnostic results.